Application of Yudian Artificial Intelligence Temperature Controller in Ethanol Recovery Systems

2020-07-06

2020-07-06

Abstract:

Ethanol is a fundamental organic chemical raw material. It can be used to produce chemical raw materials such as acetaldehyde, ether, ethyl acetate, and ethylamine, as well as products like dyes, coatings, detergents, and aerogels. During the production of aerogels and other products, ethanol can be recovered and reused. For ethanol recovery, we use distillation, employing Yudian's artificial intelligence temperature controller to precisely control the distillation and condensation temperatures to ensure the purity of the recovered ethanol.

Keywords: Ethanol Recovery, Intelligent Temperature Control

0 Introduction

Ethanol, as a raw material in various production processes, can be recovered and reused at rates ranging from 20% to 95%, depending on the specific process flow. During recovery, the ethanol is mixed with other liquid or solid components, requiring highly precise temperature control to avoid contamination from liquids with similar boiling points. Yudian's AI-526P artificial intelligence temperature controller meets the system's precision control requirements while reducing the need for analog control stages, making it convenient and efficient to use.

1 Ethanol Recovery System Design Principle

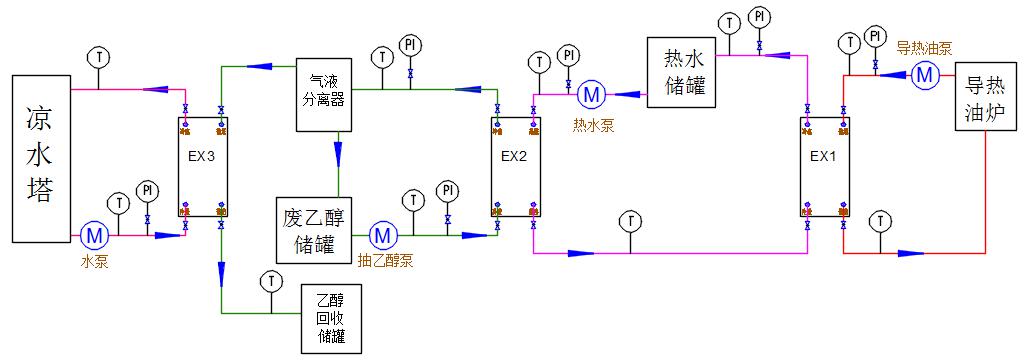

The ethanol recovery process is shown in Figure 1. In the system, waste ethanol evaporates from a liquid into a gas and then condenses back into a liquid through heat exchange. The vaporization is achieved by exchanging heat with hot water at 95°C, which is heated by thermal oil. Since the composition of waste ethanol is relatively complex, precise temperature control is required during the evaporation process. We use Yudian's artificial intelligence temperature controller to regulate the opening of the electronic ball valve on the heat fluid pipeline within the system, thereby controlling the temperature at which the waste ethanol is heated.

Figure 1 Ethanol Recovery Process Flow Diagram

2 System Temperature Control Process

Thermal Oil Boiler Module:

Due to the company's remote location and the presence of many biofuel processing plants nearby, we use a biofuel-fired thermal oil boiler. In the system, we employ Yudian's artificial intelligence temperature control system to regulate the biofuel feed rate, ensuring stable outlet oil temperature from the thermal oil boiler with an error margin of ±1°C. Additionally, we use Yudian's AI human-machine interface touch screen to monitor and record parameters such as furnace temperature, thermal oil temperature, and flow rate in real time. This data provides a basis for subsequent decisions regarding thermal oil replacement or addressing issues like ash accumulation and pipe perforation due to prolonged use.

Water Heating Module:

This module consists of two parts. One part is used for daily worker needs, where we modified the firebrick cladding of the thermal oil boiler's chimney into a water-cooled jacket system. This utilizes residual heat from combustion to heat water to around 50–60°C. We also use Yudian's intelligent temperature control instruments to regulate the water flow rate and control the temperature of the hot water storage tank. The other part is the purified water heating module used to heat ethanol. To prevent scaling, this section uses purified water. A high-temperature resistant plate heat exchanger facilitates heat exchange between the thermal oil and water. Using the Yudian AI-526P temperature controller, we set the desired water temperature. The instrument adjusts the opening of the electric ball valve on the thermal oil pipeline by regulating voltage via a thyristor. Once the temperature of the hot water storage tank reaches 95°C, the waste ethanol extraction pump is activated. Based on the actual temperature of the waste ethanol, the hot water pump’s flow rate is adjusted. Through PID settings on the Yudian instrument, the temperature of the waste ethanol outlet pipe is maintained at 82°C, ensuring that the ethanol entering the enterprise separator remains in a gaseous state and exits directly through the upper pipe into the cooling system.

Water Cooling Module:

To cool ethanol vapor, our company uses a cooling tower heat exchange system to achieve water-cooled ethanol.

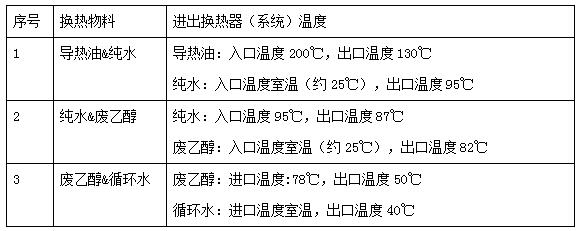

The design data for the three sets of heat exchange systems are shown in the table below:

Our company has designed a waste ethanol processing capacity of 200 liters per hour, with an ethanol recovery volume of approximately 4.8 cubic meters in 24 hours, which is sufficient to promptly handle the waste ethanol generated during current production.

The on-site electrical cabinet is equipped with six Yudian AI-706M multi-channel inspection instruments to collect temperature data from different pipelines in the system. Additionally, four AI-526P temperature control instruments are installed to separately control the opening of the thermal oil electronic ball valves in three heat exchangers, the pumping speed of the hot water pump, the feed flow rate of waste ethanol, and the pumping speed of the cooling circulating water. After using the AI-526P instrument, the previous issues of imprecise temperature control and insufficient ethanol recovery concentration have been resolved. Currently, this instrument has been operating in our company’s ethanol recovery system for temperature control for three years. The system features a self-tuning function, and during use, if there are no special requirements, it is generally only necessary to set the SV according to actual conditions and input the required temperature parameters. During the heat exchange process, we can clearly and accurately read the real-time heating temperature from the corresponding PV display. Every six months, our company performs temperature calibration on all thermocouples, and the error between the readings of the Yudian AI-526P instrument and the actual thermometer measurements does not exceed 0.1°C. Additionally, at the request of our company, we have purchased Yudian's touch screen to prepare for real-time data acquisition from the AI-706M and AI-526P instruments into the touch screen, creating a small database. This data will be transmitted via the network to office computers for real-time monitoring and analysis.

3 Conclusion

The Yudian AI-526P intelligent temperature control instrument is not only suitable for the recovery system of waste ethanol but also applicable to all working conditions involving heat exchange, distillation, and more. It features low cost and excellent stability.

References

[1] Ma Ning, Hu Yinghong. Design and Implementation of a Flexible Temperature Control System for Food Packaging Machines*. Instrumentation and Automation, 2015.3

TOP